Steve Carter of eXponentia takes us through a not uncommon fault that he observed in a Ford Mondeo TDCi, and shows how to identify and repair the fault in a timely manner.

Although this fault was unusual in its severity, the fault itself is not uncommon and given that this particular system is fitted to many cars, it won't be long before you'll be seeing one yourself, if you have not done so already.

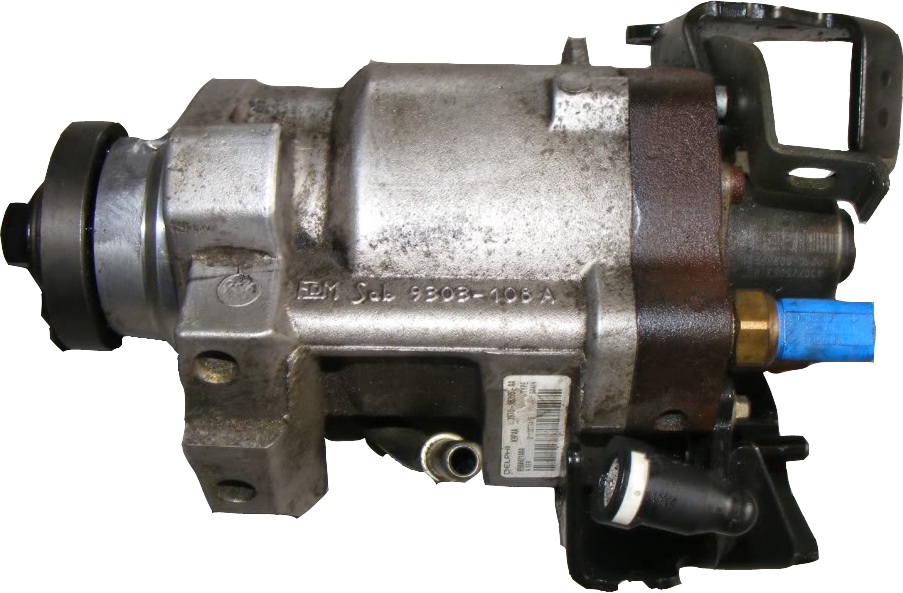

The Delphi Diesel Common Rail is fitted to the Ford Mondeo, Focus and Transit to name a few models. In this particular case, the vehicle was a 2003 Mondeo TDCi. It arrived at the garage on the back of a breakdown truck, as a result of the vehicle cutting out completely whilst driving at a moderate speed and would not restart. The vehicle had not been suffering any previous problems before this event.

The first line of approach was to see if we had any serial fault codes. This produced two codes; P0191 (low fuel pressure) and P0251 (suggested that the pressure regulator solenoid in the high-pressure pump was running an unusually high duty cycle). With these two fault codes, a picture began emerging that there was insufficient fuel rail pressure.

A catastrophic drop in fuel pressure whilst driving would cause the engine to cut out, as without the correct pressure signal, the injectors will be disabled from functioning. However, the cause of this massive drop in fuel pressure was unknown. The next stage was to check the serial live data during cranking. This showed a fuel rail pressure of just 3 bar, confirming that the first code showed insufficient fuel pressure whilst cranking. The wiring to the fuel rail pressure sensor was all in good order, so the next task was to ascertain the legitimacy of this live data reading. The second fault code suggested that the pressure regulator solenoid was running at an unusually high duty cycle. If this were the case, diesel would be drawn from the fuel tank on the low-pressure side of the pump but would not be allowed to enter the high-pressure part. As a result, the diesel would be merely returned back to the fuel tank. To perform this test correctly and safely, it is imperative that the appropriate equipment is used. I used a widely available common rail diesel testing kit, which allowed me to connect directly to the high-pressure output of the pump, reading this pressure using it’s own pressure sensor. This showed pressure from the pump of just 3 bar, confirming our live data reading was accurate.

The next stage was to remove the pressure regulator from the back of the pump and replace this with a dummy regulator, which would allow us to test the pump at full output. This test should only be carried out for a few seconds, as the pump has no ability to regulate its internal pressures. After just five seconds of cranking we show a pressure of 1740 bar. The pump was in good health and therefore the fault was with the pressure regulator, and confirmed the legitimacy of the second fault code result with regards to the unusually high duty cycle. A new pressure regulator was fitted to the vehicle and the problem was resolved.

This fault was unusual in that the pressure regulator failed in such a way that it caused the vehicle to stop running. Normally, when these regulators begin to fail, they do so in such a way that usually the customer reports poor performance and on diagnosis, this can be attributed to the low fuel rail pressure.

With the appropriate equipment and training this whole procedure took less than an hour and ended in a successful diagnosis and repair. More importantly, it was carried out safely, as dealing with 1740 bar (25230 psi) requires respect and diligence.